Article

6 DWV Installations Where Edge HP Enhances Performance

While Charlotte Pipe’s standard cast iron is well suited for the vast majority of drain, waste, and vent installations, there are certain environments that demand extra layers of defense. When conditions get tough, Edge HP Iron™ steps up with enhanced performance.

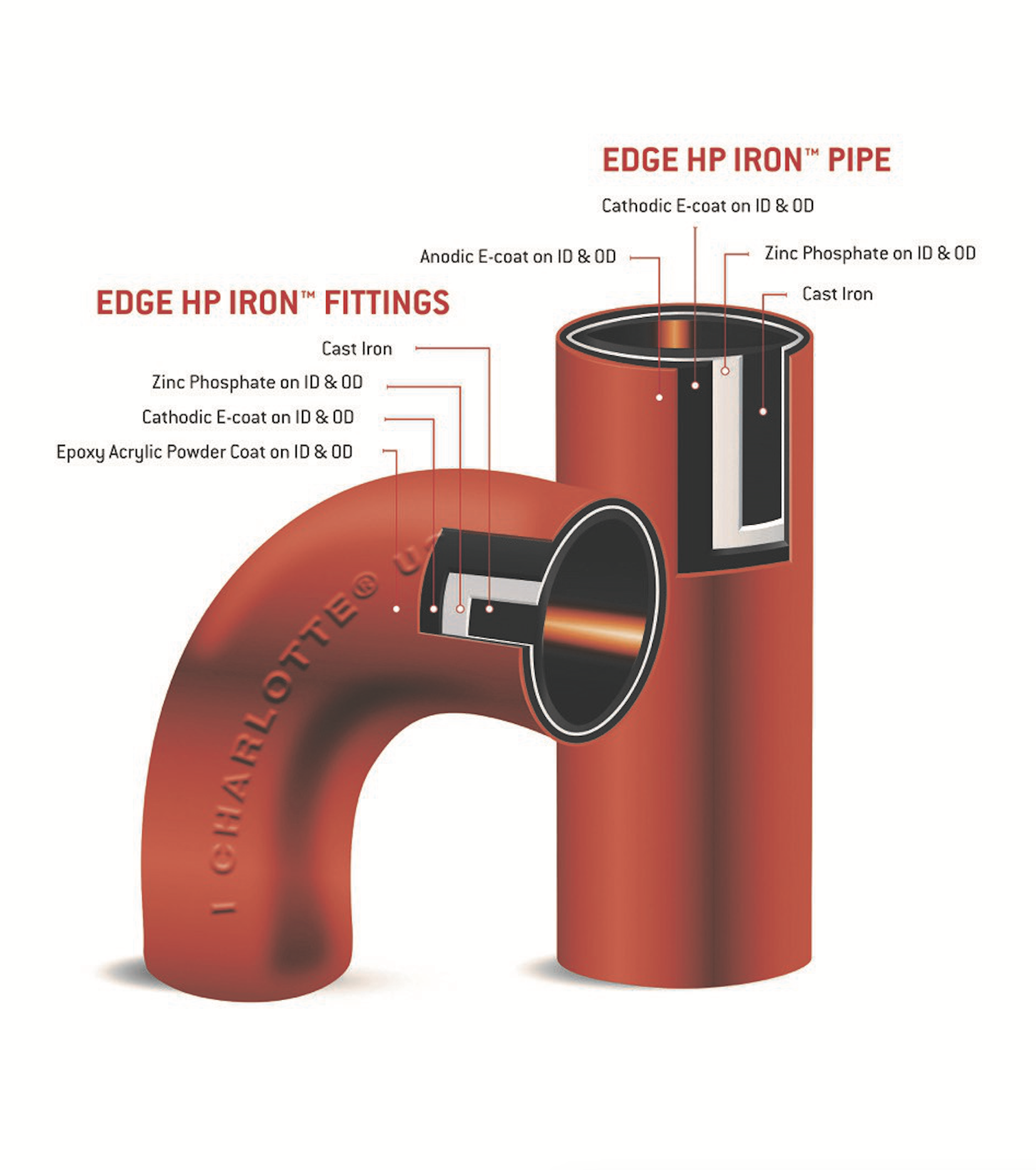

Engineered for aggressive DWV and storm drainage applications, Edge HP Iron is specially coated to protect against delamination and fight corrosion over time while also providing many of the same benefits found in traditional cast iron soil pipe.

How to Determine Whether Edge HP Iron Is Right for Your Application

Across commercial installations, Edge HP Iron is a reliable addition to hybrid piping systems, working in tandem with cast iron and PVC to meet performance demands. In applications where effluents exceed the pH range that traditional cast iron soil pipe is designed to handle, Edge HP Iron is engineered to take on the extra load. Specifically, for plumbing systems that require cast iron to handle effluents ranging from pH 2 to 12, Edge HP Iron provides the enhanced protection needed in these demanding conditions.

Charlotte Pipe’s Edge HP Iron is designed for aggressive applications and installations, such as:

- Bar Sinks: Bars regularly drain acidic and aggressive effluents, including citrus, alcohol, and cleaning agents, requiring a piping solution as versatile as Edge HP Iron.

- Casinos: With 24/7 operation and heavy foot traffic, casinos demand piping systems that perform under pressure. Edge HP Iron’s e-coating process stands up to the wear and tear of continuous use.

- Commercial Kitchens: Kitchen crews drain a steady stream of hot, greasy, and acidic waste daily. Edge HP Iron is designed to offer superior resistance to fats, oils, and cleaning chemicals.

- Hospitals: Quiet environments are essential for healing. Like traditional cast iron, Edge HP Iron helps minimize sound transfer between patient rooms, ICUs, and other care facilities. Edge HP Iron is also well suited for many healthcare applications, such as dialysis centers.

- Parking Garages: Weather, de-icing salts, vehicle fluids, and acidic runoff can all contribute to and accelerate corrosion over time. Edge HP Iron’s advanced, triple-layer system holds up.

- Soda Fountains: The acidity and sugar content of waste from soft drinks can cause unwanted buildup and corrosion inside standard systems. With Edge HP Iron, these disruptions are kept to a minimum.

While maintaining the many benefits found in traditional cast iron — including high-temperature tolerance, mechanical strength, and noise reduction — Edge HP Iron delivers added strength where it’s needed most.

4 Benefits of Edge HP Iron

Utilizing the most advanced and environmentally friendly epoxy coating process available, Edge HP Iron’s coating is electrically deposited onto the iron. The result? Three layers of enhanced protection, which:

- Enhance corrosion resistance for aggressive DWV applications: Cathodic coating reduces the amount of soluble iron in the coating, increasing its corrosion resistance.

- Handle undiluted cleaning chemicals with a pH range of 2 to 12: Traditional cast iron can handle a pH range of 4.3 to 10.

- Resist chipping or flaking thanks to chemical bonds: Anodic coating attracts paint particles, offering excellent color and gloss control.

- Ensure aggressive effluents will not delaminate the coating: E-coating evenly covers the entire product, reducing the risk of delamination and improving long-term performance.

Edge HP Iron meets or exceeds all of the coating performance requirements found within EN 877. This system also conforms to ASTM A 74 (Service and Extra Heavy), ASTM A 888 and CISPI 301 (Hubless) and is certified by NSF International.

For more information on specifying Edge HP Iron, contact your Charlotte Pipe rep.