Article

Examining the Consequences of Cured-in-Place Pipe Lining

Discover the potential risks of trenchless rehabilitation of cast iron pipe and fittings.

When underground pipes fail, replacing them can be a costly, time-consuming, and disruptive process, especially in densely populated or developed areas.

One of the most widely used solutions to this type of scenario is cured-in-place pipe lining, a technique developed to help restore damaged sanitary sewer, storm sewer, and drinking water pipelines with minimal surface disruption.

However, Charlotte Pipe explicitly recommends that any broken, damaged, or leaking cast iron pipe and fittings be replaced, not rehabilitated with CIPP lining. Let’s explore why.

What is cured-in-place pipe lining?

To save money, time, and resources, CIPP repair methods have gained attention as a way to extend the life of aging plumbing infrastructure without the need for major excavation.

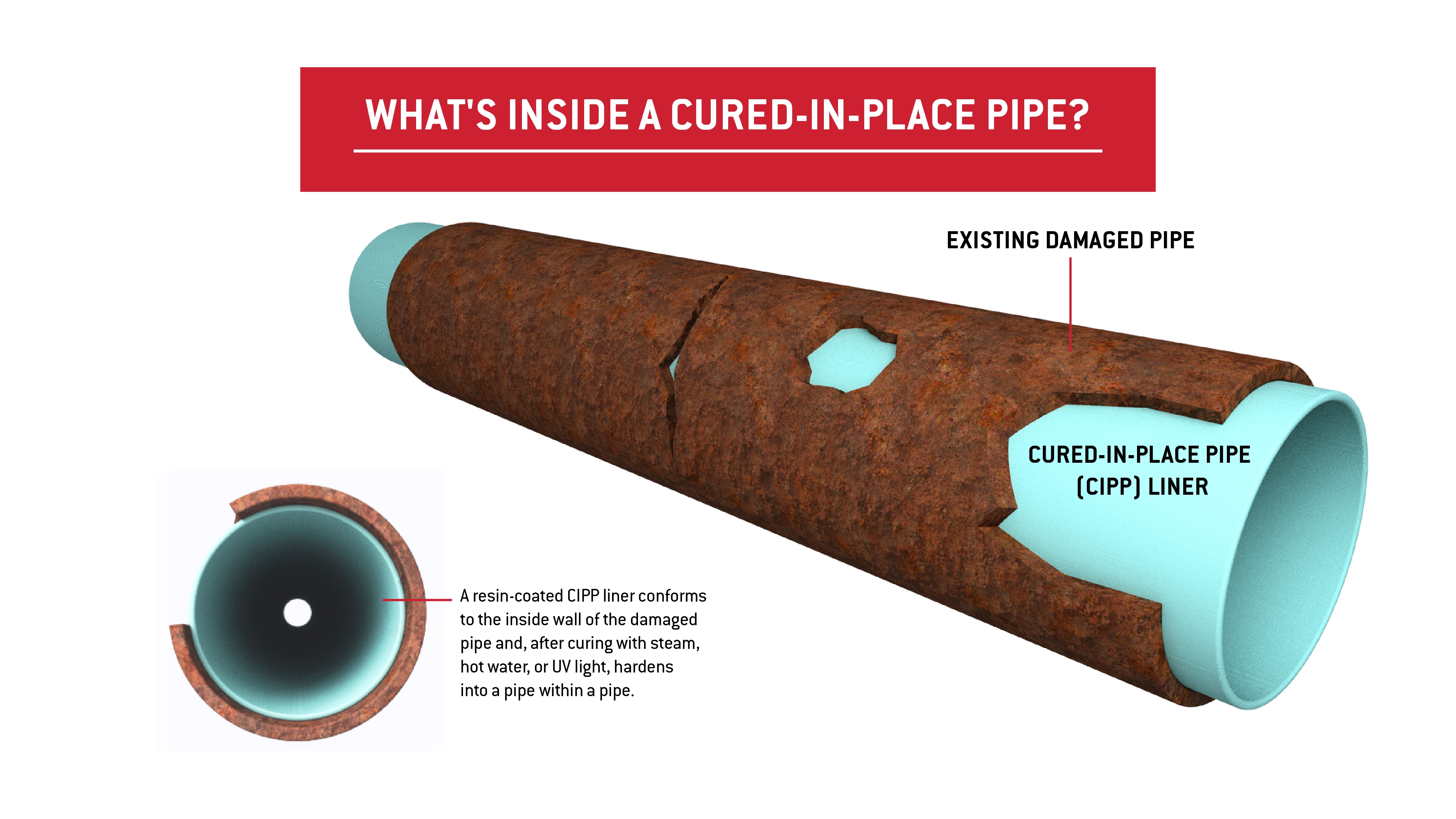

CIPP lining is a popular trenchless method to restore aging or damaged piping systems by using an inflated, heat-cured resin liner within a damaged pipe in an attempt to restore its usability.

Rather than fully replacing large networks of pipe, CIPP conforms to the condition of the existing pipe, through bellies, sags, back slopes, and other imperfections, essentially creating a new pipe inside the old one.

A successful CIPP rehabilitation is highly dependent upon properly mixing the resin, cure times, cure method parameters, and the general installation itself. As such, plumbing technicians often see several problems arise.

Charlotte Pipe explicitly recommends that any broken, damaged, or leaking cast iron pipe and fittings be replaced, not rehabilitated with CIPP lining.

5 Performance Challenges to Consider With CIPP

While viewed as a convenient solution designed to reduce infrastructure disruptions, the use of CIPP brings with it a range of performance considerations worth examining.

After investigating several trenchless rehabilitation methods, Charlotte Pipe identified five areas of concern.

- Pipe Diameter: Trenchless technologies are jointless, seamless, pipe-within-a-pipe systems. Based on its own definition, a CIPP system will decrease the inside diameter of the existing pipe, which was intentionally chosen for its unique load capacity.

- Imperfections: A nonwoven felted fabric is commonly used as a CIPP liner material. This material is susceptible to wrinkling and deforming as it is applied around corners, making it an inappropriate material for any fittings with a bend.

- Misalignment: The more flexible the CIPP liner, the more care needs to be taken during inversion to ensure the liner remains in the correct alignment.

- Maintenance: Once a line is repaired with some trenchless methods, that line can no longer be cabled or snaked with a machine, which is the most common method for clearing clogged drain lines. Instead, the line must be cleaned by hydro jetting.

- Testing: Because CIPP isn’t subject to the same testing requirements as the original pipe and lacks clear inspection guidelines, it carries a greater risk of installation inaccuracies and, ultimately, system failure.

Health Hazards Connected to CIPP

Beyond its inherent application limitations, CIPP poses an ongoing public health risk tied to sanitary sewer, storm drain, and drinking water pipe repairs across the nation.

A 2017 research study — funded by the U.S. National Science Foundation and cited by the Centers for Disease Control and Prevention — found that chemical emissions from the CIPP installations can expose workers and nearby occupants to harmful pollutants, raising significant health and safety concerns.

CIPP installation crews can be exposed to raw chemicals, forced air, steam, and other materials generated during the application process. Once the resin is heated in the curing stage, hazardous air pollutants can migrate through the piping system into surrounding areas, resulting in unwanted symptoms and health complications felt by nearby occupants.

Beyond its inherent application limitations, CIPP poses an ongoing public health risk tied to sanitary sewer, storm drain, and drinking water pipe repairs across the nation.

Avoiding Improper Repairs: What the Standards Say

Charlotte Pipe explicitly recommends that any broken, damaged, or leaking pipe and fittings be replaced. In fact, Charlotte Pipe’s warranty for cast iron pipe and fittings will not apply if:

- The products have been the subject of modification, misuse, misapplication, improper maintenance or repair, damage caused by the fault or negligence of anyone other than Charlotte Pipe, or any other act or event beyond the control of Charlotte Pipe

- The products are used with the products of other manufacturers that do not meet the applicable ASTM or CISPI standards or that are not marked in a manner to indicate the entity that manufactured them

Patching, filling, or welding cast iron pipe and fittings to correct cosmetic or material defects is expressly prohibited by the consensus standards to which the pipe and fittings are manufactured. To help determine the best path forward, see Charlotte Pipe’s limited warranty.

For questions regarding alternatives to CIPP, please contact Charlotte Pipe’s Technical Support team.